For today’s bit of good news, we are going to the amazing country of Switzerland, where I was able to geek out over an almost unimaginable technological achievement that was recently unveiled. (I didn’t actually get to go TO Switzerland, of course, but the virtual tour was cool enough!) I hope you can click on the YouTube video below to witness the unveiling of Tor Alva — the White Tower in Swiss — in the village of Mulegns in the Swiss Alps.

The tower that rises above the small village (population 11) is only four stories high — not that impressive by modern skyscraper standards — but the cake-shaped structure is entirely fabricated by a 3-D printing process. That’s correct — it was printed piece by piece in another location, shipped to Mulegns, and assembled on site. It is the world’s tallest 3-D printed structure, for the time being.

The town has high hopes for a revival of its tourism economy with the advent of Tor Alva; for now, people are traveling from all over Europe to come and see it for its architectural achievement. But beginning in July, it will host a series of staged performances and art displays celebrating the cultural heritage of Graubünden, one of Switzerland’s most famous cantons (states).

The shape of the tower reflects the area’s long history of influence on European confectionary delights — those specialty cakes and cookies that made their way to the world’s 5-star hotel kitchens beginning in the 1400’s or so. Google AI told me that Swiss confectionery is renowned for its high-quality chocolate, pastries, and hard candies. Examples include Swiss chocolate brands like Cailler, Toblerone, and Nestlé, as well as pastries like Zuger Kirschtorte (a cherry cake) and Bündner Nusstorte (a nut pie). (I do not believe that Swiss Cake Rolls from Little Debbie are included, however.)

How does one build a 4-story homage to Swiss cakes and candies from a 3-D printer? Here’s the somewhat technical explanation from architect Michael Hansmeyer and Professor of Digital Building Technologies Benjamin Dillenburger:

Instead of relying on traditional concrete formwork, they opted for an additive manufacturing process, whereby an industrial robot applies the concrete layer by layer into free-form elements without any supportive casting molds. The design is based on complex algorithms that generate the ornamental and the structural aspects at the same time.

To make this process possible, a specially developed concrete was needed. It had to be soft enough to bond the delicate structures, while hardening quickly enough to support the subsequent layers without support molds. A novel mixture was developed for this purpose. Just before the concrete leaves the pressurized nozzle, two additives are blended into the mixture, allowing the characteristic droplet-like relief on the columns to be achieved.

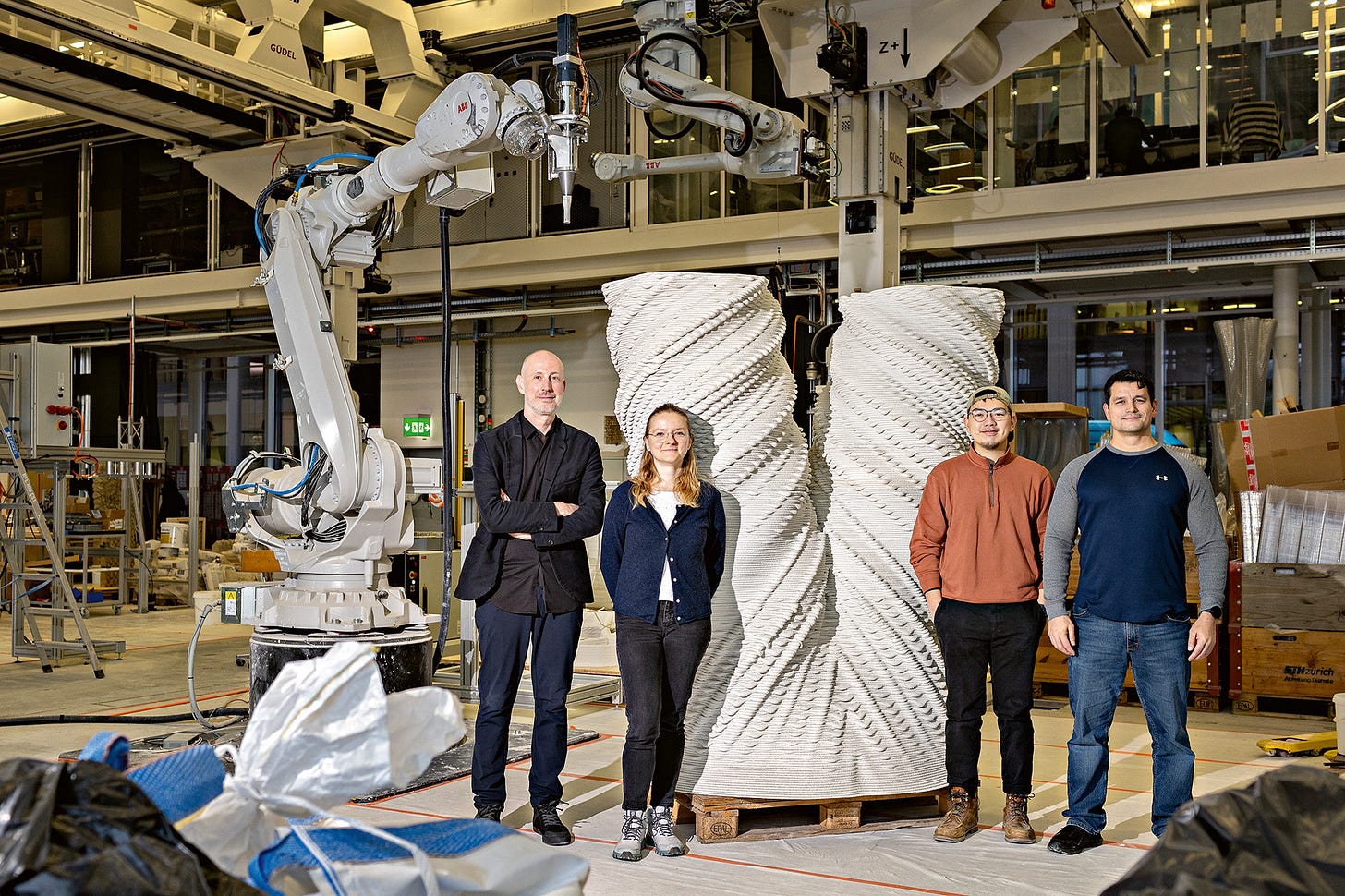

Professor Dillenburger and his student assistants are pictured below.

Yet another YouTube video shows the printing and assembly process here:

I will admit that 3-D printing is a process that still bewilders me and blows my mind — but to see something on this scale achieved with such beauty and precision is truly amazing.

One last tidbit to make the whole chapter even more interesting: the village of Mulegns lies at the opening of the Julier Pass through the Swiss Alps. This follows the route of an ancient Roman roadway constructed through the mountains, itself quite a marvel of technology in its time. One last picture below shows a Roman column that still remains beside the modern road leading through the mountains. I’m not sure which fascinates me more: the 3-D cake tower or the remnants of a 2,000-year old Roman road!

If you’re interested in booking your own tour of Tor Alva and a fabulous Swiss vacation, you can check it out here at MySwitzerland.com. Have a great weekend, everybody!

Now where are my Swiss Cake Rolls…?

Share this post